WHS program sparks a passion for a career

It’s been a semester to remember for one Wimberley High School senior who is on his way to becoming a certified welder just in time for graduation. Kyle Clark is spending a couple of school days every week at Patriot Erectors-Dripping Springs, an opportunity made possible through the WHS Practicum Program and supportive business partners.

Goals for this program include industry certification, hands-on training and career readiness. Clark is checking the box for each of these goals and having a great time doing it. The bonus—role models with a strong work ethic.

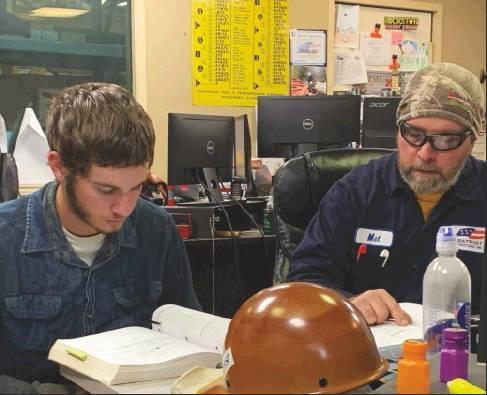

Clark is apprenticing under the kind and experienced tutelage of Melvin Bell, a quality control specialist at Patriot Erectors-Dripping Springs and an 18-year veteran of the industry. While Clark is quiet and not interested in talking much about himself, his eyes light up when he talks about his mentor.

“Mel reminds me of my grandpa,” he says. “I admire his work and how he works. My grandpa taught me the same work ethic, and I’ve always thought it was important to work just like that.”

While Clark says his favorite part of the practicum program is welding, there are several important steps that he had to master before graduating to a welding torch. Prior to stepping on the floor, he trained in safety, reading welding symbols and understanding drawings under the guidance of Patriot team members. Once on the shop floor, safety continues to be a focal point for Clark’s journey with the addition of hands-on curriculum on fabrication layout, welding techniques and quality.

Today, with Bell at his side, Clark puts on hearing and eye protection, and gloves, and practices welding steel pieces, all important preparation for certification. He won’t work on a customer’s product until he receives all the training and certification.

“When we start a project, we can’t flip a building to make all of the appropriate welds. You have to be able to weld in different positions, so we start with the basics, like a horizontal weld, and from there you have the opportunity to improve your welds and learn how to weld vertically and overhead,” said Bell.

When Bell is inspecting his apprentice’s work, he checks the overall appearance of the weld and also conducts a destructive examination to assess how strong the weld is by trying to break apart the welded material.

In addition to working in the shop, students in this program learn about project management—an opportunity to experience the day-to-day responsibilities of a construction project manager, understand the importance of the document control section and work closely with an associate detailing manager.

“By participating in this program, my team and I find great satisfaction in seeing the students learn and grow right before our eyes,” said Brian Weber, Patriot Erectors-Dripping Springs Director of Projects. “My team tells me that when they are presenting the kids with new concepts it might take two or three times for the students to understand it, but it’s really satisfying to watch them get it, and see the light bulb go off.”

As a father himself, Weber knows the importance of workforce preparation that goes beyond the classroom or shop.

“If you give them a certain level of responsibility and respect, and model and reinforce the importance of showing up to work, being on time and listening to their mentor, and making sure they understand what they are being taught, it gives them confidence,” said Weber.

To pursue a career in welding at one of Patriot Erectors’ fabrication shops, employees must complete their OSHA-10 within 30 days of being hired, which students complete through the welding and carpentry shop at WHS. Candidates must also complete a welding certification administered by one of Patriot’s employees who hold a D.1.1. certification through the American Welding Society.

Patriot offers an excellent benefits package to complement a beginning paycheck of $13.50 an hour, depending on the welder’s experience and skill level. Industry pay range is between $13 to $26.

There are 78 students enrolled in the WHS practicum program this year—64 of them are sponsored in Wimberley.